US Cellar Systems is an industry leader in the design and manufacture of wine cellar refrigeration systems California. They provide a variety of installation options that can accommodate all applications. Their series of cooling systems and refrigeration accessories are engineered to meet the different specifications and requirements of wine cellar builders and designers, as well as HVAC professionals.

Climate controlled systems manufactured by US Cellar Systems are developed with flexibility in mind, because their products can adjust to each unique characteristic of every custom residential or commercial wine cellars. Their line of wine cellar refrigeration systems and components can provide multiple solutions for private wine cellars, commercial wine storage spaces, wine cabinets, and wine closets.

US Cellar Systems wine cellar refrigeration products include HS (High Static) Series, CC (Cabinet Cooler) Series, LPQ (Low Profile Quiet) Series, RM (Rack Mount) Series, VRM (Vertical Rack Mount) Series, DQ (Dual-air Quiet) Series, and WM (Wall Mount) Series.

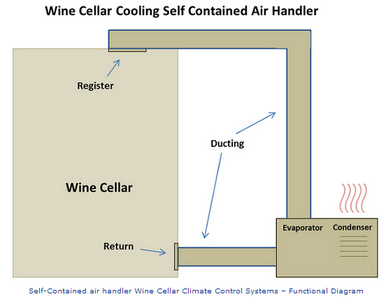

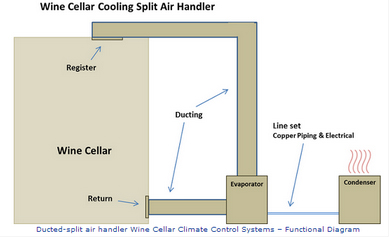

The HS Series is designed to be installed some distance away from the wine cellar, thus reducing noise and vibration in the storage area. This cooling unit can be mounted in different areas of a residential or commercial property, such as the attic, basement, or roof top. This remote setup allows wine collectors to maximize their wine storage space.

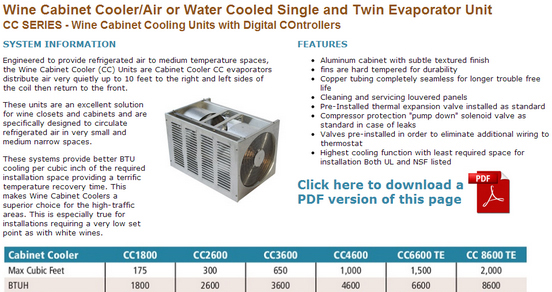

The CC Series is specially built for wine cabinets and wine closets in which air flows through small and narrow spaces. This cooling series circulates air up to 10 feet to the left and right of the evaporator coil. This unit is designed for efficient and quiet operation in refrigerated wine cellars.

The LPQ Series is mounted on the ceiling and is ideal for wine cellars with arched ceilings. Refrigerated air is supplied to the room from behind the coil system down a wall, and returned to the angled front of the unit to produce better air flow.

The RM Series is engineered for refrigerated wine cellars, located in medium to high temperature areas. This unit is the easiest to install and the most flexible. It can be mounted horizontally or installed within the racking system. The RM Series consists of several access panels that provide versatility in air distribution.

The VRM Series is similar to the rack mount units in terms of features. The only difference is that they are mounted vertically. This wine cellar refrigeration systems California is an ideal solution for utilizing unused corners or areas in a wine storage space.

The DQ Series is specifically designed for wine cellars that have long and narrow layouts, and for wine rooms that are accessed regularly. Return air is pulled in at the bottom and cool air is circulated into the room in two directions with medium to high velocity.

The WM Series is the unit of choice for refrigerated wine cellars with confined or restricted spaces, as well as those with constrained shapes. As the name suggests, the Wall Mount Series is mounted on the wall and only protrudes about one inch into the storage room.

US Cellar Systems work alongside some of the best in the wine cellar industry, such as Coastal Custom Wine Cellars and Wine Cellar Specialists. They are committed to providing the ideal solutions for creating the perfect, refrigerated wine cellar environment, as well as extending exceptional customer service to clients before, during, and after the installation process.