Take Me Straight to the Wine Cellar Cooling System – Heat Load Survey Form

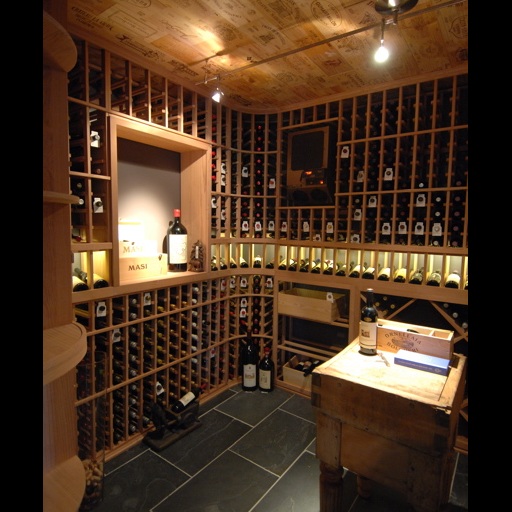

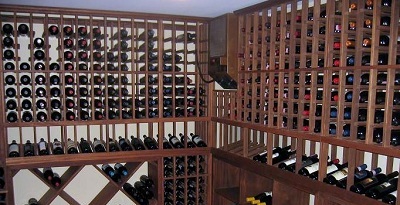

Most wine cellar cooling systems companies offer only a few sizes of wine cellar refrigeration units. These are often matched to a sizing standard of cubic feet. A very useful starting point when determining the volume to be a climate controlled wine storage area. However, this does not include ANY details specific to the Custom Wine Cellar.

The cubic feet method assumes basic standards in construction, usage, and operation. It assumes minimal insulation is used. Not more or NONE. That is generally the only consideration included. It does not account for many very common variables that can be incorporated into a Custom Wine Cellar which are calculated when using an actual heat load survey.

What are these variables that affect a wine cellar cooling systems choice and why are they important?

– Glass

Windows, doors, or walls are NOT considered when sizing by cubic feet.

Any glass in a Wine Cellar or Wine Cabinet is hugely important to compensate for when sizing. The insulation value of dual pane glass is ~R2. This allows a good deal of the cooling to be transferred through the glass. Increasing the amount of equipment required to keep the temperature stable. If it is not considered and smaller equipment is used the chance it will keep up with the needs of the space are slight. However, it is very likely that the equipment will run all the time. This will cause additional problems of very low humidity, extremely high cost of operation, or premature equipment failure not covered by the warranty.

Single pane glass should be avoided like the plague! The slightest leak in a door seal can cause your beautiful cellar to look more like a restaurant pie case. When the cold and warm air mix the water vapor instantly condenses to water droplets. This causes a ‘fog’ on the glass and can eventually lead to staining of the surrounding areas if left unattended. It is not the fault of the equipment and cannot be compensated for. It is a construction issue.

– Insulation

R value, above or below grade, ambient temperature all makes a difference.

Cubic feet estimates R11 insulation as the only factor in the equation. Obviously if there is no insulation to be used this estimate will be wrong. No company ever suggests it is acceptable to use no insulation in a Wine Cellar. Just the same it happens all the time. If a wine room like this is insisted upon by the client, even against better judgment, at least plan for it. Just the same as underestimating glass a larger system will be required or there will be problems.

On the other hand, if more insulation is being used a smaller system may be recommended. This is especially true if the Wine Cellar is to be below grade. Ground temperatures tend to be considerably lower than normal “ambient temperatures” or the conditioned air surrounding the cellar. Therefore much less equipment is required to maintain a stable temperature.

Over-sizing can create problems of a different kind. If the refrigeration system is too large it will only need to run a fraction of the time it should to keep temperature. This may sound great at first but it is not. Commonly known as “short-cycling” will damage the equipment causing failures that may not be protected under the warranty. In addition, the equipment running a predetermined cycle is how the humidity is balanced in the room. If the equipment runs too little the wine cellar’s humidity will increase. Condensation could occur especially if there are defects in the construction. If left alone labels could fall off bottles, water staining wood surfaces, and mildew and/or mold will grow.

– Lighting

Type, # of fixtures, hours used impact the heat of the Wine Cellar.

It used to be quite common to use can lights in a Wine Cellar. Anyone who has ever changed a light bulb knows lights can get very hot, pretty quickly. Imagine you intend to leave these on so you can show off your beautiful Custom Wine Cellar at a summer dinner party lasting several hours. Maybe you just want to leave it on to enjoy it yourself for a few hours each evening after a hard day’s work. Now think of that heat that the refrigeration has to overcome. This is another question in the heat load survey that should be answered as accurately as possible.

If in doubt USE LED LIGHTING! It produces so little heat it does not need calculated into the heat load. Modern LED lighting is now available in many designs, colors, and shapes. It does not have to look like a disco or a Christmas tree. Bulbs can fit in standard fixtures and even work with dimmers or remotes.

– Set Point

Activity, recovery and thermal mass are all things to consider when committing to a “Set Point” temperature for a Wine Cellar.

It is agreed by most experts that 55f is the ideal temperature to store wine, red or white. Both are SERVED at different temperatures. White wines or champagnes should be served preferably below 45f and reds at room temperature. Long term storage warmer than this can accelerate or damage the aging process, colder can slow or even stop it.

Wine Cellar Cooling Systems – Whites Wines & Champagnes

Some Wine Cabinets are designed with the intention of using a serving temperature for whites and champagnes. This would not be allowable with a cubic feet estimate alone. Especially since most Wine Display Cases like this are primarily glass and in hospitality locations. In a restaurant it is very possible that during peak hours the doors will be opened many times per hour. This requires a careful choice of which system is best suited to improve the recovery time and bring the Wine Storage Unit back to normal temperature.

Wine Cellar Cooling Systems – Thermal Mass

Thermal mass describes the temperature of the liquid within the bottles, cases, or even barrels stored in a Cellar. Thermal mass adjusts about 75% more slowly than air temperature does. If there is a lot of room temperature wine loaded into a cellar at one time it is perfectly normal to take up to several hours for the refrigeration to gently bring the temperature to where it is set. Once that is achieved the thermal mass reacts to changes slowly and will assist the stabilization in the room. The equipment will return to normal operation. Setting the thermostat to go colder WILL NOT make it go FASTER. It will put unnecessary stress on the equipment especially if a lower set point was not used in the heat load survey.

Sudden and drastic changes to the temperature of wine are far more detrimental than having it too cold or too warm for a short while.

– Additional features

Refrigerators, TV, Electronics, Fireplaces

Many designers like to add unique features to custom cellar designs. It is important to note that all appliances and electronics give off heat. These things should be considered carefully and are strongly discouraged.

H2: The USCS Heat Load Survey Form

Click here to go to the USCS Heat Load Survey Form. This information should be collected as accurately as possible and sent to us for a free load calculation and estimate. It will help us provide to you the correct equipment options for each unique design.

It will save you the money, time, and aggravation of improperly sized equipment.